Our services

MAS Technics your partner in

- On-site machining

- Circular welding

- Alignment and measurements

- Machine mounting

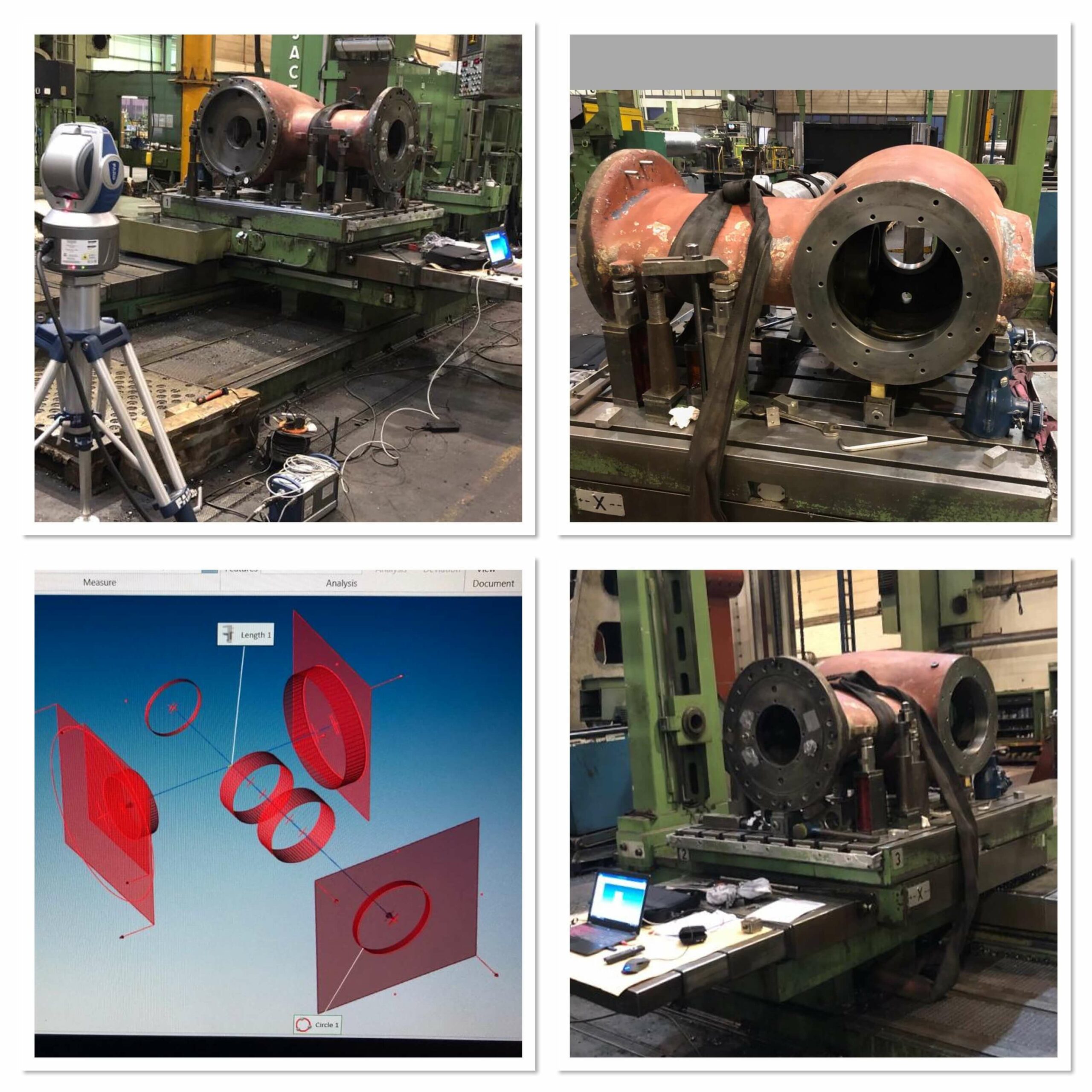

- 3D measurements

- Specials on requests

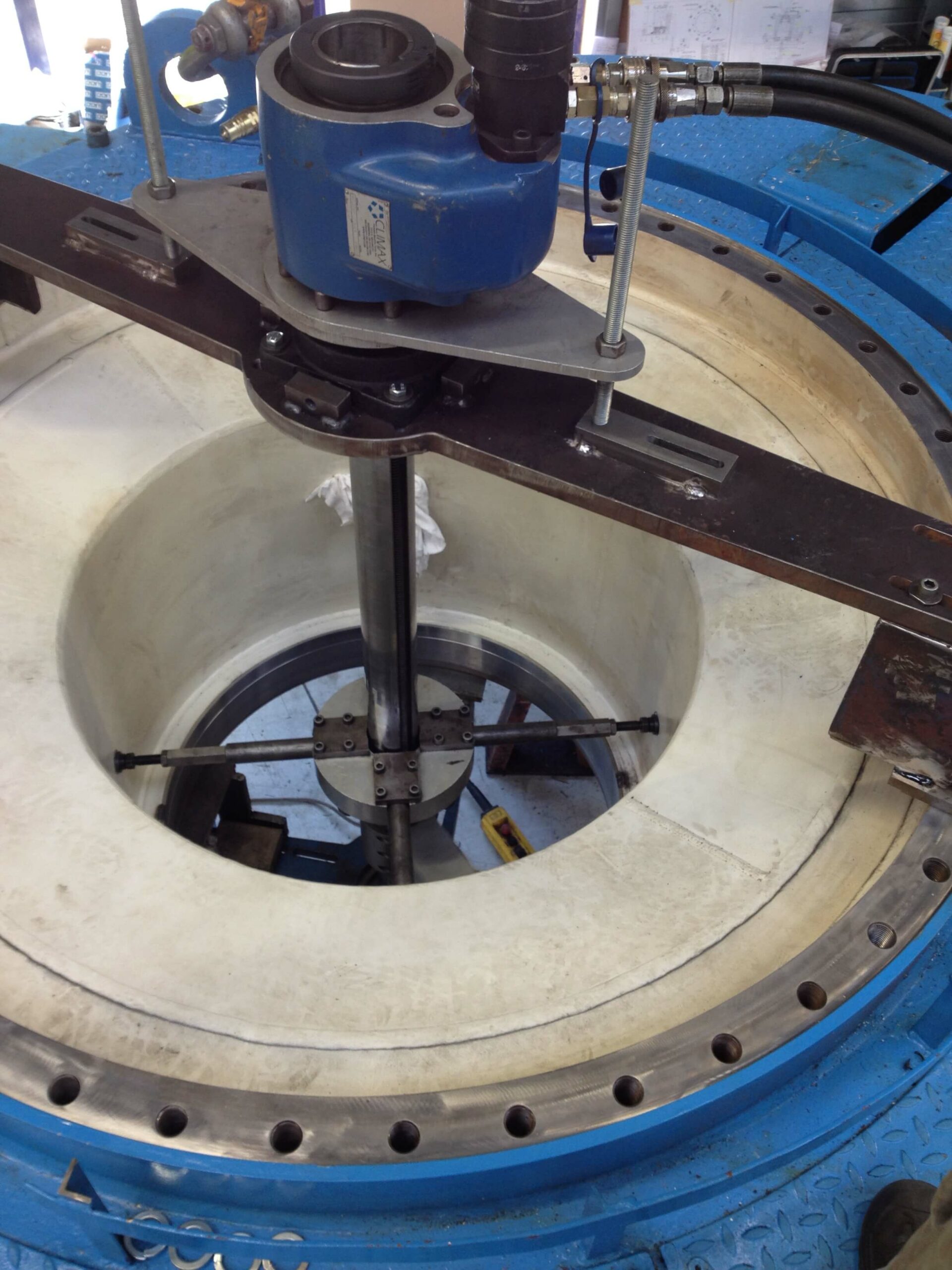

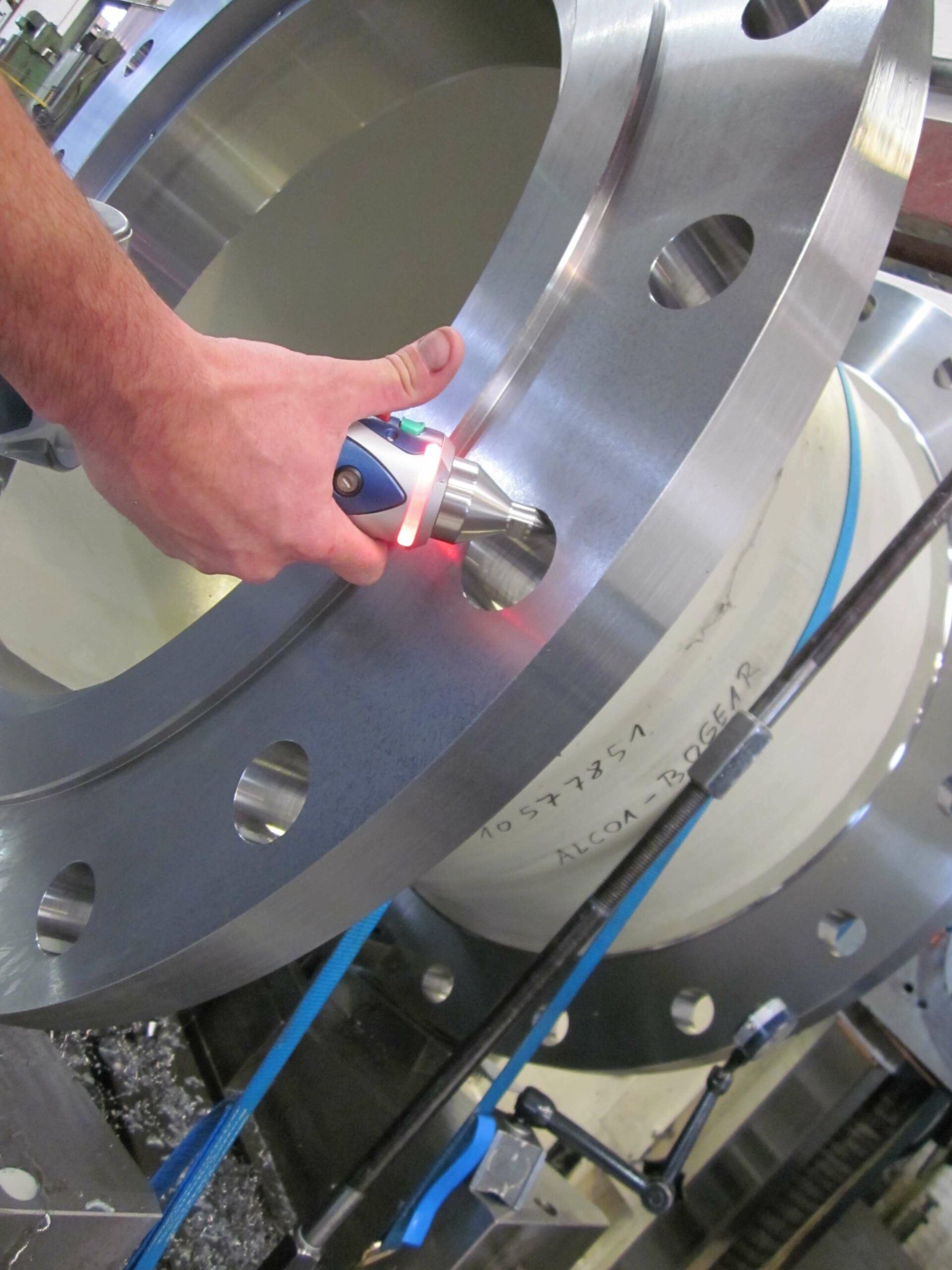

On-site machining

MAS Technics B.V. adapt a solutions driven approach providing our clients with the most technologically advanced on-site machining techniques and services worldwide.

Why on-site machining?

Time saving, cost reducing, no transport of your construction, machine downtime can be avoid, high quality.

- Flange facing

- Line boring

- Linear/surface milling

- Circular milling

- Pipe cutting

- Honing

- Drilling

- Tapping

- Grinding

- Keyways

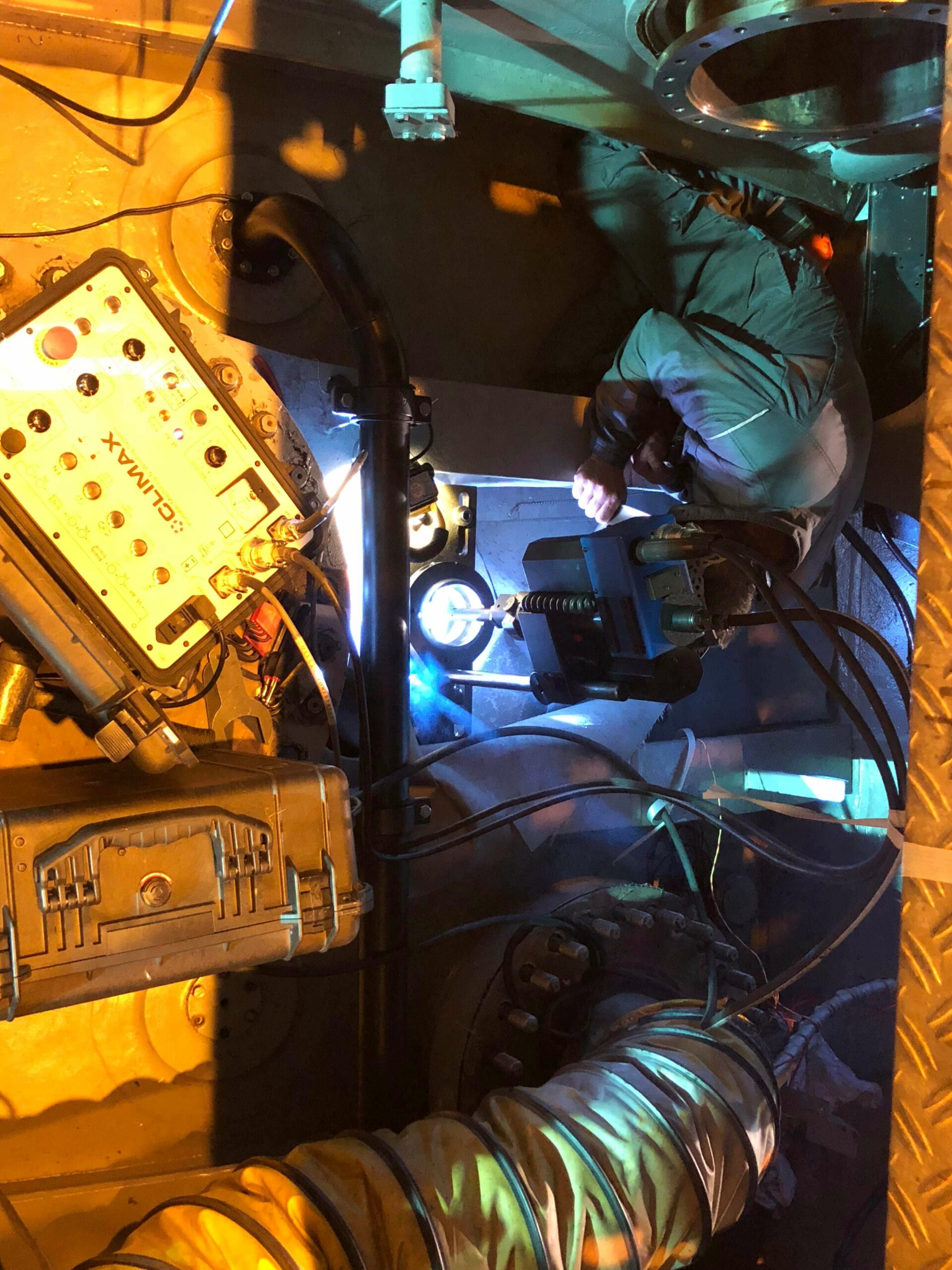

Circular welding

- Bore welding repairs to original

- Overlay welding

- Surface welding

- 309Lsi and 316Lsi

- Certificate, WPS

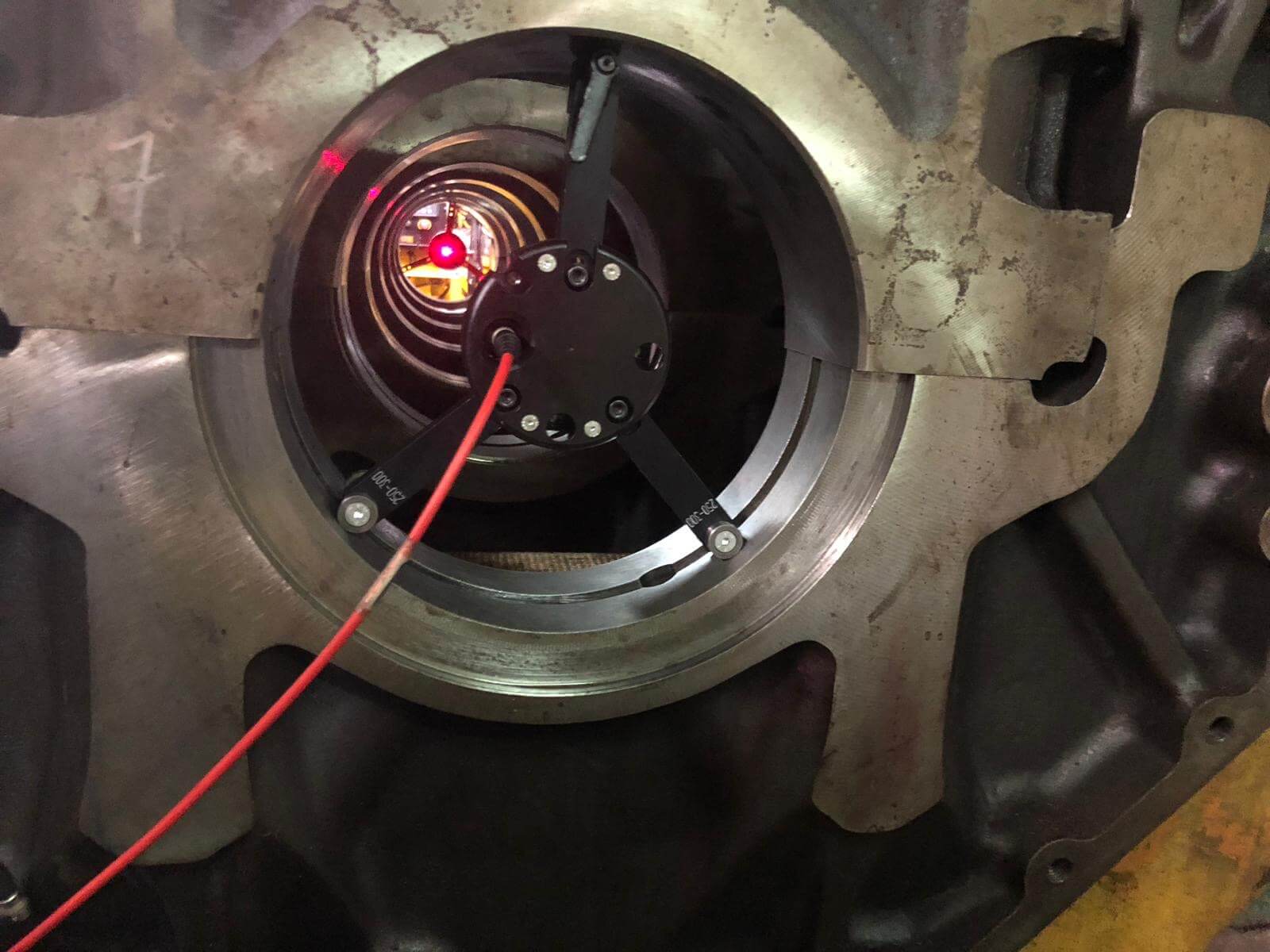

Alignment and measurements

- Laser alignment

- Machine alignment

- Rotating equipment

- Shaft alignment

- Bore measurements

- Straightness measurement

- Propulsion / stern tube measurements

In every situation, the most efficient energy transfer will occur if the two connected shafts are co-linear, the shafts behave as if they were one structure. When shafts are misaligned, forces are generated in the coupling. Any deviation in offset or angle will inevitably mean that the shaft will try to find a common axis of rotation. Energy will be lost in the coupling and increased loads will be placed on any mechanical components which provide for rotation, seals, bearing housing, etc. Misalignment manifests itself in five interrelated problems.

- Increased vibration

- Increased energy loss

- Increased load on bearings, seals and other mechanical components

- Lifecycle reduction

- Resonance in components

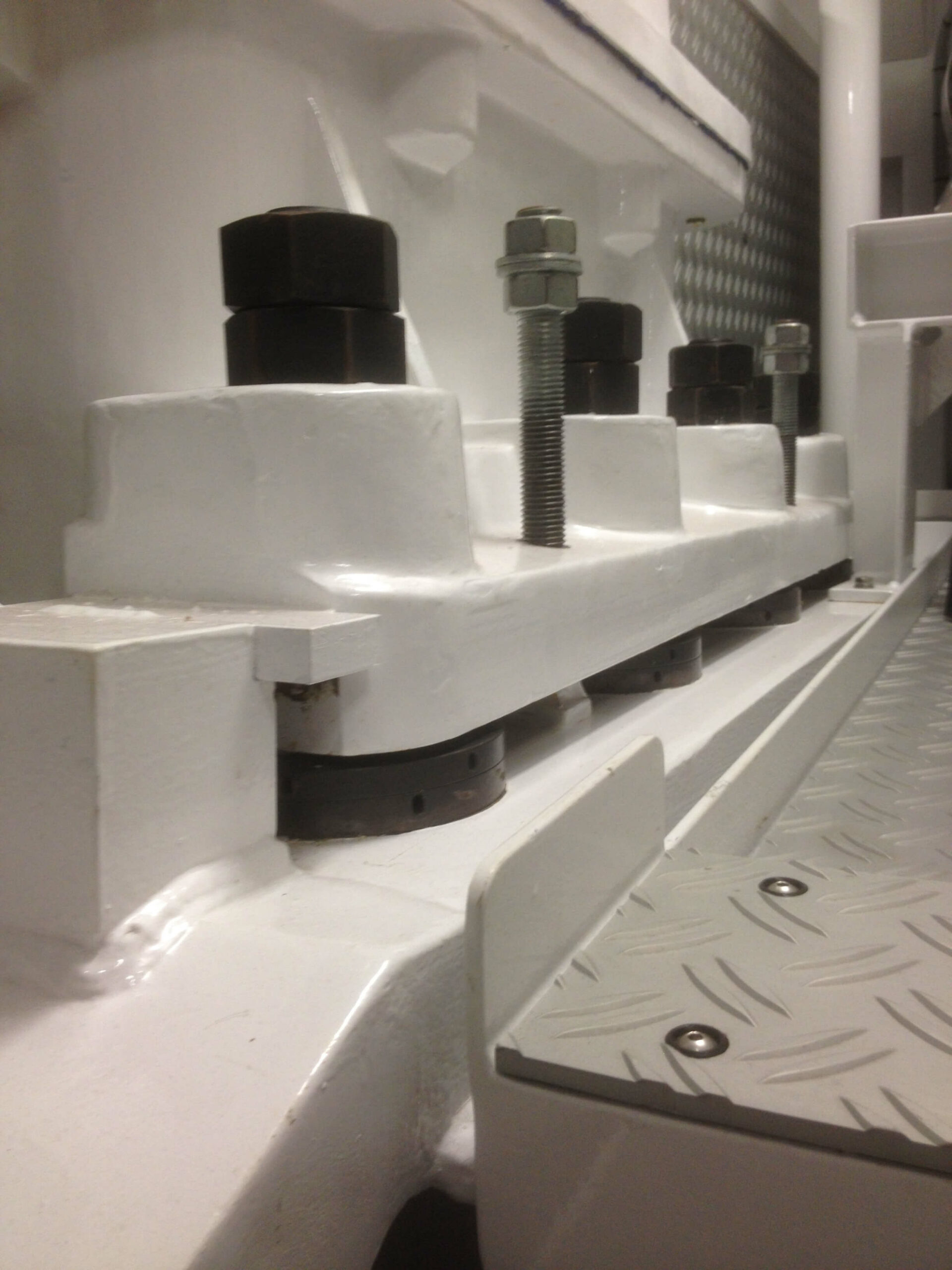

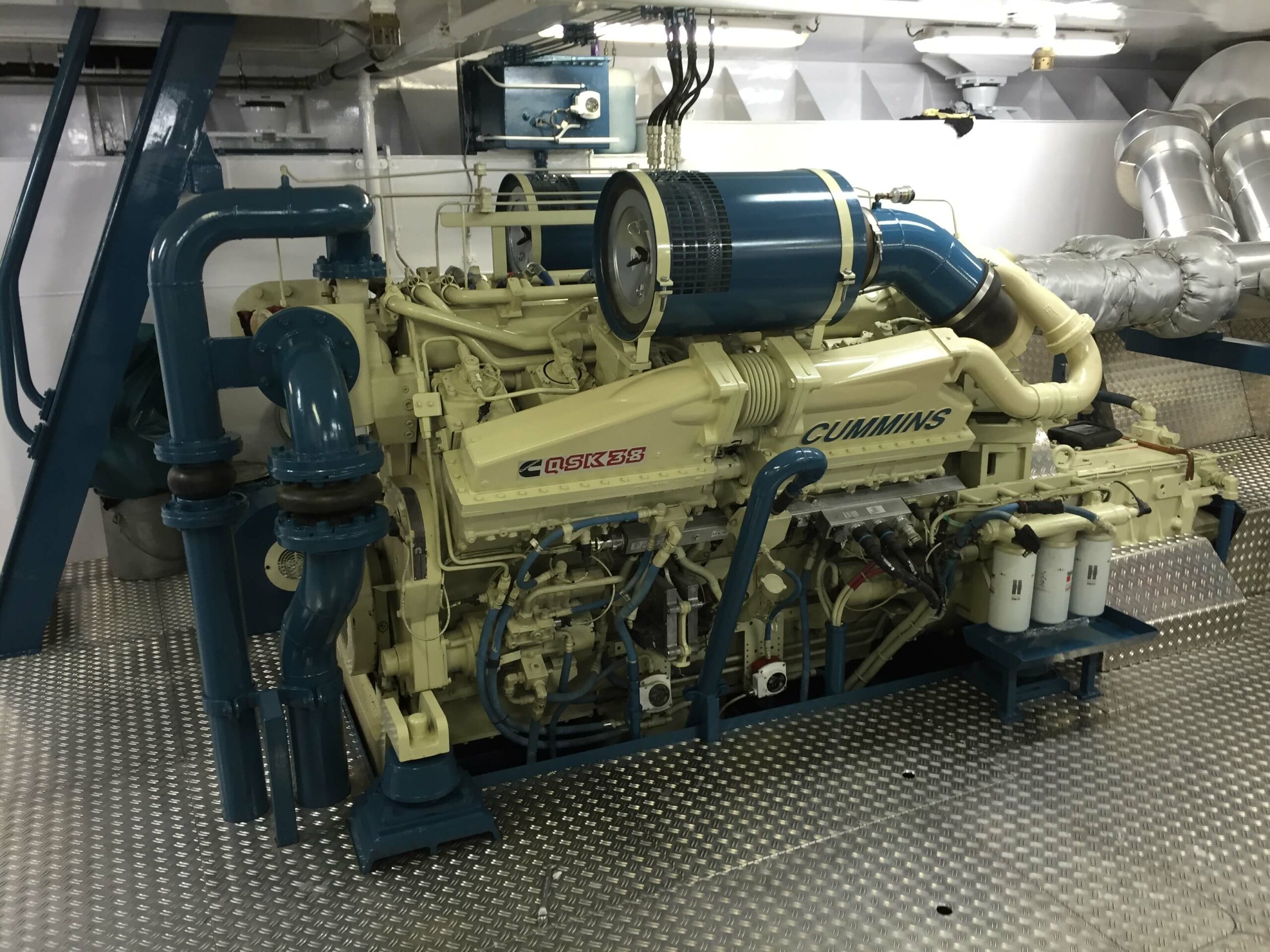

Machine mounting

- Epoxy (Chock fast orange , Epocast 36 , Loctite PC 7202)

- Vibracons / Rota chocks

- Rubber mounts, conical mounts

- Resilient mounts

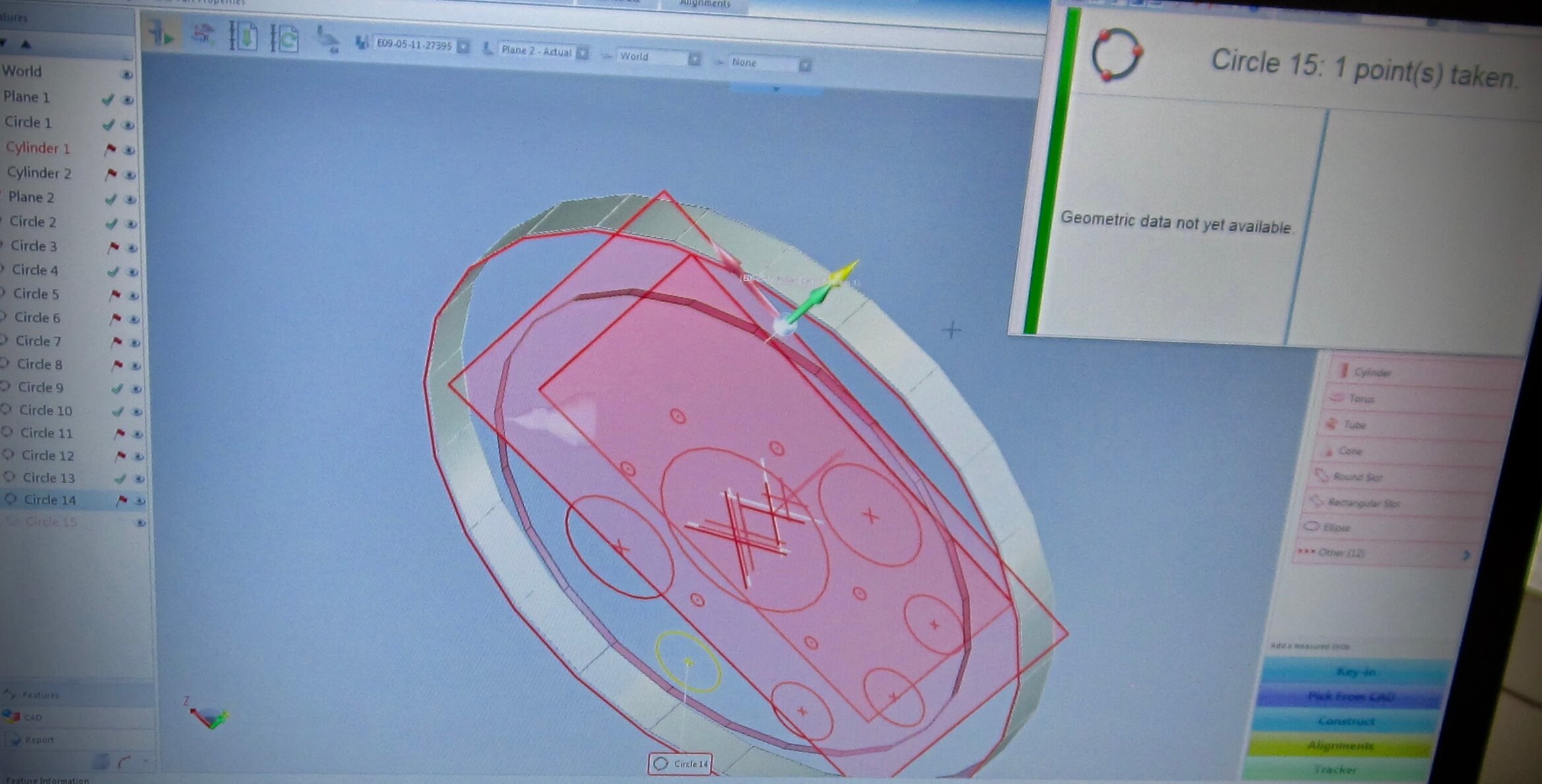

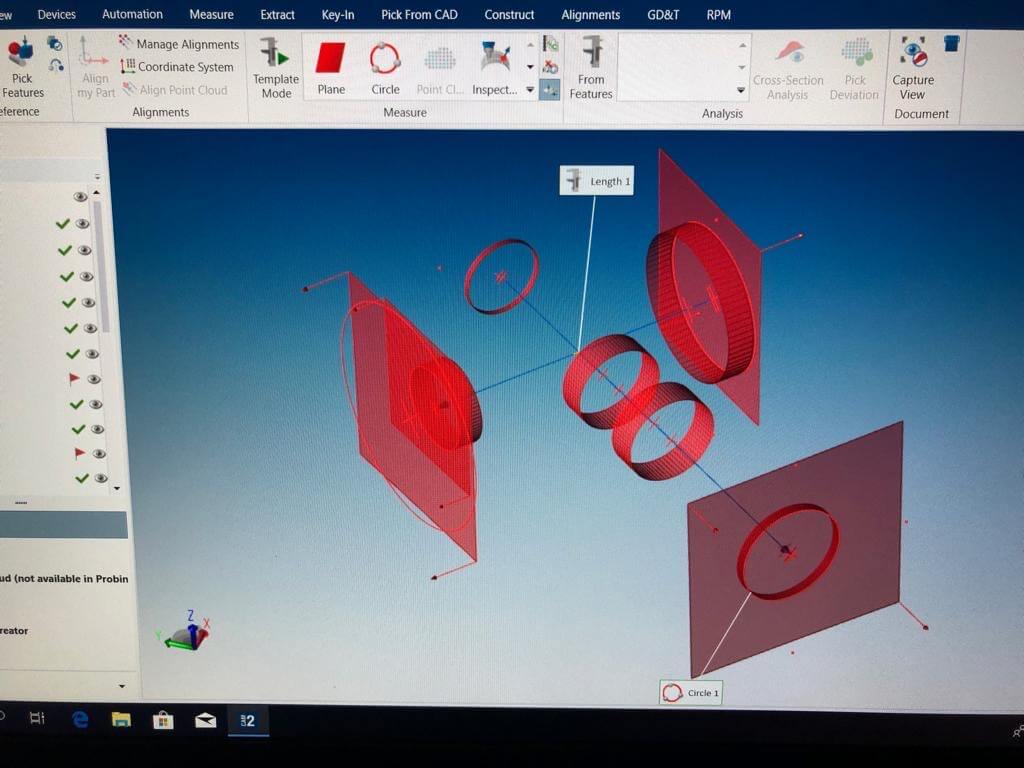

3D Measurements

- 3D laser tracker

- 3D measurements

- 3D scanning

Specials on request

- Not just standard? Contact us for the options and we will have a look to solve your problem.

- Custom build machines